|

The WHITE

This is just a "standard" Scirocco, with some extras :-)

Body

A full restauration of the bodyshell has been performed and a roll cage has been fitted for safety reasons.

The time to design a proper body jig was well spent when the underside of car needed attention (a dirty job!).

Suspension & brakes

Bilstein Racing shocks with Eibach springs.

(180/60/60 // 180/60/40, front // rear) with helper springs (40/60/40 // 40/60/30, front // rear).

Eibach numbering (180/60/40):

180 = unloaded length

60 = diameter of spring

40 = spring rate (in N/mm)

Tarox drum (slotted) at the rear, at the front ventilated Tarox 256X20 plain disc with Wilwood Dynalite II 4-pot Tarox drum (slotted) at the rear, at the front ventilated Tarox 256X20 plain disc with Wilwood Dynalite II 4-pot

Brake balance bar and stainless steel braided PTFE hose at the front as well as at the rear, with copper line between.

Gearbox/transmission

The opportunity to install an 02A gearbox fitted with a Quaife differential was to good to miss (especially as a gearbox was needed to "the YELLOW").

Manufactured a new engine mounting on gearbox side and modified the rear one (I am a big fan of the "Volvo Valp" engine mount). The side mounts are of the Metalastic type purchased from MecMove. Front is a "standard" polyurethane.

Got a tip that drive shafts from a 53B (Scirocco II) with the 16V engine should be a perfect fit for this gearbox. But, compared to the old shafts a clear difference in length can be noted. I have a feeling that this need some modifications.

Engine

Ahh, the engine! The heart for an engine geek like me.... :-)

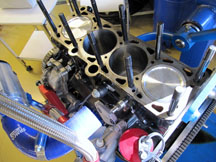

The base was a 1800 cc where I have replaced the standard crankshaft with a 92.8 mm stroke version. This, together with a bore of 82.5 mm results in a 2000 cc engine. I started with modified 16V pistons, more of that later. Camshaft is a "noname" from Germany with a 300/11.75 profile. Cylinder head modification by "Nille", valve size 42/35. Valve springs by Schrick. Engine management system P8Pro from DTA.

With the 02A gearbox came a different (bigger) flywheel. It was not only big, it was heavy as well. But after some turns in the mill, the weight was reduced, from 9.4 to 6.0 kg (-36%).

After just a short time in the dyno, I lost compression in the cylinders. The pressure was a little bit too much for the old standard gasket. Thanks to Rejsa.nu a got a tip to use the gasket from a 2.0L 16V instead. This of the new Multi-Layer Steel (MLS) type (part no 048 103 383D) and will hopefully do the trick. At the same time I realized that I needed new pistons, the few hours had not been good to them...... A little bit strange to find out that I needed to make a special custom order for my engine. I couldn't find the dimension that I was looking for, that is a compresson ratio which would suit my engine. Thanks to Köhler Racing pistons from Wössner arrived.

Light (lighter) is good for my engine. Piston assembly mass reduced from 429 to 371 gram (-14%).

Weight adjusted conrods, oil pan with some internal baffels and high tensile studs instead of screws.

The distributor modified to act as housing for the cam shaft sensor. K-Jetronic injector holes will be utilised for Idle Air Control.

TPS installed on the inlet manifold.

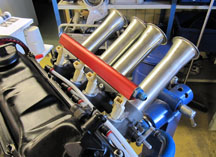

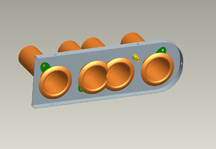

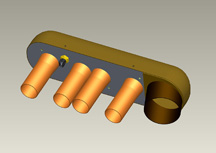

A new fuel rail manufactured as well, the new electronic injectors installed where mechanical ones were situated a long time ago.

Inlet air chamber designed, manufactured and installed on car.

|